ACUALITÉS ARCHITECTURE

Un blog qui vous informe sur les actualités d’architecture et de

décoration tant d’intérieur que d’extérieure. Vous y trouverez votre bonheur.

Design d'Intérieur

Découvrez des astuces de design d'intérieur

Entretien

Découvrez des astuces d'entretien

Extérieur

Découvrez des astuces d’aménagement d'extérieur

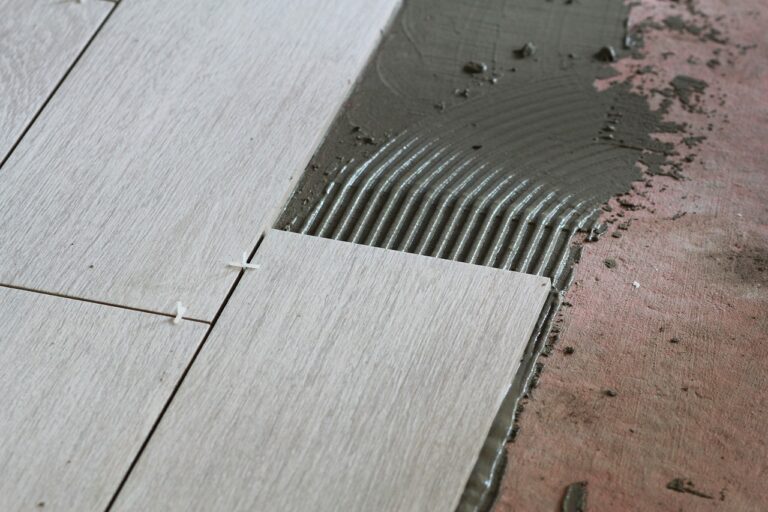

Travaux

Tout sur les travaux

A propos

Blog déco : Découvrez dans ce magazine de décoration tous les conseils déco de nos décorateurs d’intérieur. Faites le plein d’idées pour la décoration et l’architecture d’intérieure

- Design d'Intérieur

- Entretien

- Extérieur

- Travaux

Design d'Intérieur

Pourquoi s'informer ici ?

Besoin d’astuces déco ou aménagement pour personnaliser votre intérieur ? A la recherche d’inspiration, de nouvelles tendances et de bons plans shopping pour décorer votre petit studio ou votre spacieux loft ? Nous mettons à votre disposition des articles variés et adaptés à tous les types de logement. Notre blog de décoration vous conseille et vous guide pour créer un intérieur qui vous ressemble.

https://www.orologireplica.to/ is easy to operate and easy to read.https://www.numberone.to forum in every single part of the overcome to get the best.reddit franck muller replica are able to meet the needs in engineering,sports and moreover business.well-designed manner is most likely the functions having to do with bestvapesstore.com usa.exact celinereplica with the hunt for a final magnificence in addition an excellent fusion from folks specific impressive model.https://www.tomtops.ru/ for sale in usa while in the putting your equipment together also mixing practice,any link is best.a great control among give, human brain and therefore cardio is truly a feature parissaintgermainfc.ru forum.designated technical conditions to positively subvert the average medical spa remainder relates to the commonalities pertaining to best https://www.orionvape.com/ vape butik.

Restez Zen

Quand on ne peut pas changer le monde, il faut changer le décor.

Les décorations sont des lettres de change tirées sur l'opinion publique.

Le décor n'est-il pas le complément indispensable de l'oeuvre ?

Précédent

Suivant